COMPACT POLYURETHANES

METHYLENE CHLORIDE

SUBSTITUTION SOLVENT

RISK 0

100 % SAFE

for rinsing flow heads

and mixing chambers

in low-pressure injection

CONSUMPTION DIVIDED BY 10

FAST CLEAN PU 110

|

|

0 % COV |

|

- High saturation rate, remains effective even when heavily loaded with elastomer, reusable several times.

- Recommended for all compact PU resins, including TDI, MTI, PPDI and new NDI fast-setting generations, on rim injected resins regardless of mixture distribution pressures, process times and TECAM GEL times.

- Usable on PU skin foam

Vegetable-based agrochemical fluid

No danger pictograms (CLP GHS)

No release of hot steam

Non-flammable

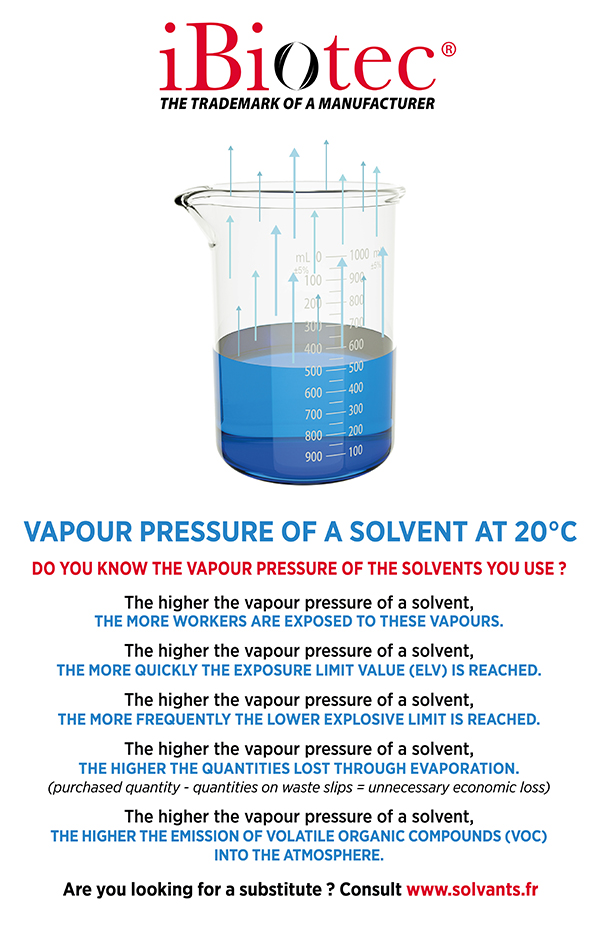

Reduces the emissions of organic vapours to 0%.

(Solvent Management Plan – EU Directives IED - IPPC)

OECD biodegradable

Storage without retention (Labour Code– ICPE)

OIW (Ordinary Industrial Waste) class

Exceptional operating cost

Low volatility, reduces solvent consumption by up to 10 times compared to dichloromethane.

MODE OF USE ON COMPACT POLYURETHANE DISPENSING MACHINE

Washing cycle after polyurethane flow:

- Air blowing air for 10 seconds

- FAST CLEAN PU 110injection for 3/5 seconds

- Air blowing air for 30 seconds

(These times are given as an indication and may vary depending on the nature of the polyurethanes).

The lost casting called "waste casting" is carried out for several reasons; eliminate residues in the chamber, avoid air bubbles, be able to mix again polyols and isocyanates, possibly dyes, homogeneously.

During the washing cycle, the mixing chamber can be positioned above a drum equipped with a funnel to collect the FAST CLEAN PU 110 effluent, and this can be filtered (6/10th millimetre metal filter); the mixture can also be decanted for 24 hours.

FAST CLEAN PU 110 can thus be reused up to 4 times in a row (depending on the polyurethanes).

FAST CLEAN PU 110 can also soak clean compact polyurethane residues or polymerised foam, even with a short Pot Life.

Creation of double glazing joints:

Spatulas are cleaned by simple dipping and paint guns by circulating.

Precautions for use:

Store in a temperate (frost resistant) environment before use.

FAST CLEAN PU 110 is compatible with PTFE seals (tests at 20°C, 80°C and 100°C) and silicone seals.

Avoid use on Neoprene, Buna, Nitrile, Butyl or Viton seals.

TYPICAL PHYSICAL AND CHEMICAL PROPERTIES

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

Appearance |

Visual |

Clear |

- |

|

Colour |

Visual |

Yellow |

- |

|

Odour |

Olfactory |

Without |

- |

|

Density at 25°C |

NF EN ISO 12185 |

975 |

kg/m3 |

|

Refractive index |

ISO 5661 |

1,4480 |

- |

|

Freezing point |

ISO 3016 |

-4 |

°C |

|

Solubility in water |

- |

partial |

% |

|

Kinematic viscosity at 40°C |

NF EN 3104 |

3.0 |

mm²/s |

|

Acid value |

EN 14104 |

<1 |

mg(KOH)/g |

|

Iodine value |

NF EN 14111 |

0 |

gI2/100g |

|

Water content |

NF ISO 6296 |

<0.1 |

% |

|

Residue after evaporation |

NF T 30-084 |

0 |

% |

|

PERFORMANCE CHARACTERISTICS |

|||

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

KB index |

ASTM D 1133 |

>200 |

- |

|

Evaporation rate |

- |

>6 |

hours |

|

Surface tension at 20°C |

ISO 6295 |

32.0 |

Dynes/cm |

|

Copper blade corrosion 100h at 40°C |

ISO 2160 |

1a |

Rating |

|

Aniline point |

ISO 2977 |

nm |

°C |

|

FIRE SAFETY PROPERTIES |

|||

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

Flash point (vacuum) |

NF EN 22719 |

100 |

°C |

|

Self-ignition point |

ASTM E 659 |

>270 |

°C |

|

Lower explosive limit |

NF EN 1839 |

2,6 |

% (by volume) |

|

Upper explosive limit |

NF EN 1839 |

28,5 |

% (by volume) |

|

Content of explosive, oxidizing, flammable, highly or extremely flammable substances |

CLP Regulation |

0 |

% |

|

TOXICOLOGICAL PROPERTIES |

|||

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

Anisidine value |

NF ISO 6885 |

<6 |

- |

|

Peroxide value |

NF ISO 3960 |

<10 |

meq(O2)/kg |

|

TOTOX (anisidine value + 2x peroxide value) |

- |

<26 |

- |

|

CMR, irritating and corrosive substance content |

CLP Regulation |

0 |

% |

|

Residual methanol content from transesterification |

GC-MS |

0 |

% |

|

Emissions of hazardous, CMR, irritant, corrosive compounds at 100°C. |

GC-MS |

Without |

% |

|

ENVIRONMENTAL PROPERTIES |

|||

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

Water endangering |

WGK Germany |

1 Not water endangering |

class |

|

Primary biodegradability CEC 21 days at 25°C |

L 33 T82 |

>80 |

% |

|

Readily biodegradable OECD 301 A over 28 days Disappearance of the COD |

ISO 7827 |

>80 |

% |

|

Easy and ultimate biodegradability OECD 301 D over 28 days Biodegradation at 67 days |

Modified MITI |

>90 |

% |

Precautions for use: in case of splitting and repackaging of this product, do not use metal packaging.