SERIMAX FAST 80

SOLVENT FOR WASHING

AFTER SCREEN-PRINTING

SCREEN PRODUCTION

Can be removed with water

Immediate action time

Not classified as flammable, flash point: 80°C

Compatible with all screens

Silk

PA Polyamide-Nylon

PEN UP Polyester

EVA Ethylene Vinyl Acetate

No voltage defects

No effect on block making

AREAS OF USE

Automatic washer

Manual brushing and high-pressure rinsing

Spray washing machine

Wetting

PHYSICAL AND CHEMICAL PROPERTIES

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

Appearance |

Visual |

Clear |

- |

|

Colour* |

Visual |

Amber |

- |

|

Odour |

Olfactory |

Fruity |

- |

|

Density at 25°C |

NF EN ISO 12185 |

977 |

kg/m3 |

|

Refractive index |

ISO 5661 |

1.4270 |

- |

|

Freezing point |

ISO 3016 |

< -25 |

°C |

|

Solubility in water |

- |

100 |

% |

|

Kinematic viscosity at 40°C |

NF EN 3104 |

2.4 |

mm²/s |

|

Acid value |

EN 14104 |

0 |

mg(KOH)/g |

|

Iodine value |

NF EN 14111 |

0 |

gI2/100g |

|

Water content |

NF ISO 6296 |

0.0 |

% |

|

Residue after evaporation |

NF T 30-084 |

0 |

% |

|

PERFORMANCE CHARACTERISTICS |

|||

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

Kauri Butanol index |

ASTM D 1133 |

190 |

- |

|

Evaporation rate |

- |

200 |

min |

|

Surface tension at 20°C |

ISO 6295 |

34.5 |

Dynes/cm |

|

Copper blade corrosion 100h at 40°C |

ISO 2160 |

1a |

Rating |

|

FIRE SAFETY PROPERTIES |

|||

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

Flash point (vacuum) |

ISO 2719 |

80 |

°C |

|

Self-ignition point |

ASTM E 659 |

> 230 |

°C |

|

Lower explosive limit |

NF EN 1839 |

0.7 |

% (by volume) |

|

Upper explosive limit |

NF EN 1839 |

7.0 |

% (by volume) |

|

TOXICOLOGICAL PROPERTIES |

|||

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

Anisidine value |

NF ISO 6885 |

0 |

- |

|

Peroxide value |

NF ISO 3960 |

0 |

meq(O2)/kg |

|

TOTOX (anisidine value + 2x peroxide value) |

- |

0 |

- |

|

CMR, irritating and corrosive substance content |

CLP Regulation |

0 |

% |

|

Residual methanol content from transesterification |

GC-MS |

0 |

% |

|

ENVIRONMENTAL PROPERTIES |

|||

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

Biodegradability |

OECD 301 |

easily biodegradable |

- |

|

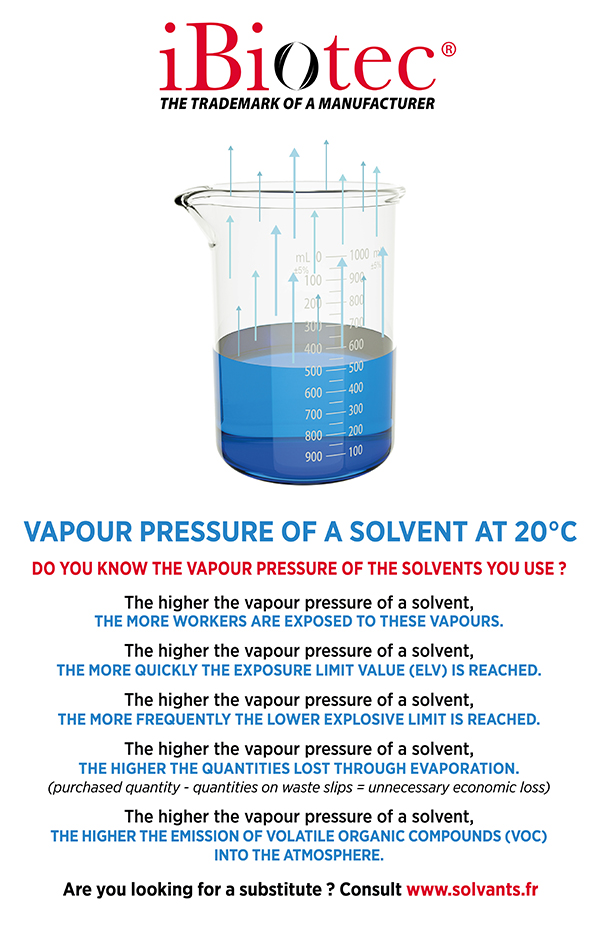

Vapour pressure at 20°C |

- |

0.1 |

kPa |

|

VOC content (Volatile Organic Compounds) |

- |

60 |

% |

|

Sulphur content |

GC-MS |

0 |

% |

|

Benzene content |

ASTM D6229 |

0 |

% |

|

Total halogen content |

GC-MS |

0 |

% |

|

Chlorinated solvent content |

- |

0.00 |

% |

|

Aromatic solvent content |

- |

0.00 |

% |

|

Environmentally hazardous substances content |

CLP Regulation |

0 |

% |

|

Content of compounds with a GWP |

- |

0 |

% |

|

Content of compounds with an ODP |

- |

0 |

% |

Precautions for use: in case of splitting and repackaging of this product, do not use metal packaging.

In the field of screen printing, the wide variety of inks used means that a number of different cleaning solvents are required.

This is more of a problem for custom screen printing companies that print on a wide variety of media.

Traditional cleaning solvents are mixtures of benzene hydrocarbons (CMR: Carcinogenic, Mutagenic or Reprotoxic) with additives containing glycol ethers and cyclohexanone, aromatic solvents such as toluene or xylene, ketones such as acetone, methyl ethyl ketone or methyl isobutyl ketone, or ethyl acetate, or methylene chloride.

All of these solvents, whether pure or mixed, are extremely dangerous in terms of toxicity, the environment and their fire risk.

While ink manufacturers are developing increasingly high-performance water-based products, operators usually continue using dangerous cleaning solvents, given the low versatility of use of water-based solvents on the resins of different chemical families (matrices).

The SERIMAX products offered by IBiotec solve all of these problems.

In line with CLP 1272/2008 (amended version 1079/2016), no ‘danger’ pictogram as regards toxicity to operators.

Suitable for all ink families, including amalgams and dry inks.

|

MEDIA |

INKS |

|

PAPER, CARDBOARD (posters, wallpapers, particle boards, etc.) |

Nitrocelluloses Vinyls Acrylics Pliolites (styrene acrylics) |

|

METALS AND ALLOYS

|

Epoxies Polyesters

|

|

LACQUERED METALS (packaging, signs, etc.) |

Nitrocelluloses |

|

PLASTIC MATERIALS (with or without flame treatment, Corona effect) Cellulose acetate butyrate, polystyrene Acrylonitrile, butadiene, styrene copolymers Polymethyl methacrylates Polyvinyl chlorides, polycarbonates Polyesters, saturated polyesters, PET, PE |

Cellulosic Vinyls Acrylics |

|

NATURAL TEXTILES, SYNTHETICS, LEATHER |

Plastisols Polyurethanes |

|

GLASS, ENAMEL, PORCELAIN |

Epoxies |

|

ALL MEDIA PCB imageable soldermask, screen printing |

UV (photocrosslinkable) EB (electronic bombardment) UV acrylates |

PRESENTATIONS

200 L Keg 20 L drum

|

|