iBiotec

NEUTRALÈNE® 1079

CLEANING SOLVENT

SPECIAL SOLVENT FOR INKS, RESINS,

PAINTS, VARNISHES AND SIMILAR, UNCURED

NOT CLASSIFIED FLAMMABLE ICPE

EASILY AND QUICKLY BIODEGRADABLE

ODOURLESS SOLVENT, USABLE PURE OR DILUTED IN WATERR

FOR WASHING MACHINES, PARTS CLEANERS

BY WIPING OR IMMERSION

|

|

Satisfies Commission

Recommendation (EU) 2017/84

of 16 January 2017 on the monitoring

of mineral oil hydrocarbons in food

|

|

56,7% |

NO HAZARD PICTOGRAM

European Regulation CLP 1272/2008

SGH - GHS Regulations

CLEANING AND WASHING SOLVENT SPECIFICALLY FOR RESINS, INKS, ADHESIVES, GLUES, FRESH PAINT AND SIMILAR

Ternary solvent mixture.

Guaranteed free of hazardous, harmful, irritating, or sensitising substances.

Non-flammable, usable cold or in hot baths.

Declassification of ATEX zones.

Very high solvent power KB index greater than 150.

Usable pure, diluted in water, rinsable in water.

SMP optimisation

Solvent Management Plan

(IED Directive)

Solvent input/output material balance

Low volatility, reduction of consumption.

REDUCTION OF SOLVENT EMISSIONS

ODP 0 PRP 0

CLASS NHIW (non-hazardous industrial waste) Reduced cost of destruction.

Freezing point -80°C. Outdoor storage is authorised.

Without retention (labour code. Unlabelled product

ICPE environmental code. Non-polluting product).

Reduction of industrial risk, operating loss, third-party liability

(insurance code)

DESCRIPTION

Azeotropic mixture Powerful solvent for all degreasing operations as well as hot or cold washing of machine parts.

Especially recommended for eliminating inks, resins, traces of glues or adhesives.

APPLICATIONS

Rinsing of ink ducts in offset printing and flexography.

Soaking of spray nozzles for resins, primers, paints, foams, glues.

Soaking of brushes, spiked rollers, and tools for the application of polyester resins and gel coats.

Soaking and scrubbing of stainless steel coating or photo-engraving cylinders, or deflector rolls.

Cleaning of coating or printing machines using a cloth.

Cleaning of resin application machines and painting booths using a cloth.

Centrifugal washing of tanks and mixers for resins, monomers, and master mixtures.

Cleaning by spraying and brushing of manufacturing tanks and mixers.

Use on solvent parts cleaners, pure or diluted in water, according to the nature of the paints and resins.

NEUTRALÈNE® 1079 is particularly recommended for the cleaning of textile belts for silk screen printing, by scraping. Dissolves contact adhesives, resins that cure under UV, carboxy alkyl cellulose and nitrocellulose resins.

PHYSICO-CHEMICAL PROPERTIES

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

Appearance |

Visual |

Fluid |

- |

|

Colour |

Visual |

Colourless |

- |

|

Smell |

Olfactory |

No smell |

- |

|

Density at 25°C |

NF EN ISO 12185 |

953 |

kg/m3 |

|

Refraction index |

ISO 5661 |

|

- |

|

Freezing point |

ISO 3016 |

-80 |

°C |

|

Water solubility |

- |

100 |

% |

|

Kinematic viscosity at 25°C |

NF EN 3104 |

3.5 |

mm²/s |

|

Acid index |

EN 14104 |

0 |

mg(KOH)/g |

|

Iodine index |

NF EN 14111 |

0 |

gI2/100g |

|

Water content |

NF ISO 6296 |

<0.01 |

% |

|

Residue after evaporation |

NF T 30-084 |

0 |

% |

|

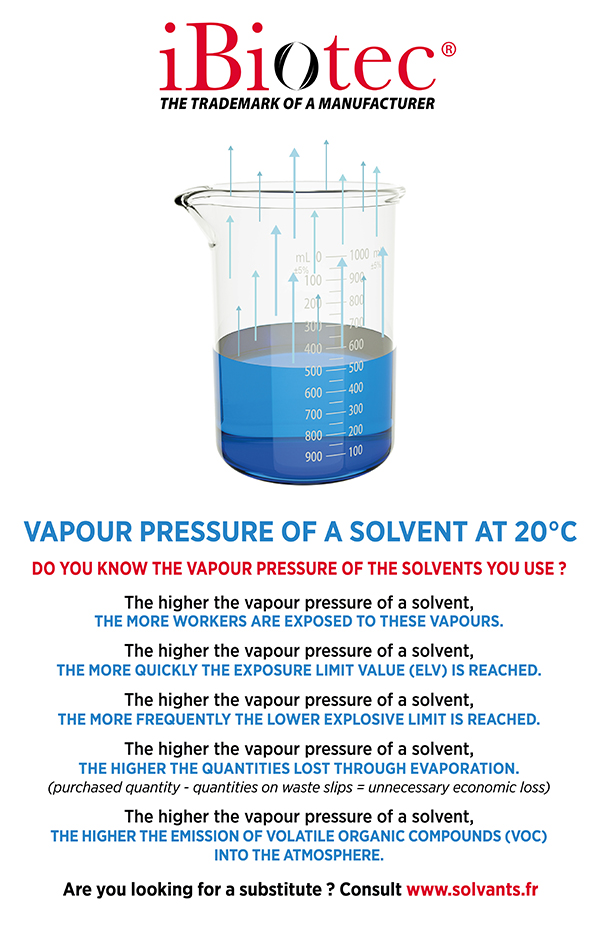

Steam pressure at 20°C |

NF EN 13016-1 |

0.3 |

hPa |

|

PERFORMANCE PROPERTIES |

|||

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

KB index |

ASTM D 1133 |

> 150 |

- |

|

Evaporation speed |

n-butylacetate = 1 DEE = 1 |

0.030 350 |

Index |

|

Surface tension at 20°C |

ISO 6295 |

28.8 |

dyne/cm |

|

Breakdown voltage |

NF EN 60156/IEC 156 |

nm |

Volts |

|

Copper blade corrosion 100 h at 40°C |

ISO 2160 |

1a |

Measured value |

|

FIRE SAFETY PROPERTIES |

|||

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

Flashpoint (closed tank) |

ISO 2719 |

82 |

°C |

|

Self-combustion point |

ASTM E 659 |

> 220 |

°C |

|

Lower Explosive Limit |

NF EN 1839 |

1 |

% (volume) |

|

Upper Explosive Limit |

NF EN 1839 |

14 |

% (volume) |

|

Explosive, oxidising agent, flammable, highly or extremely flammable substance content |

CLP Regulation |

0 |

% |

|

TOXICOLOGICAL PROPERTIES |

|||

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

Anisidine index |

NF ISO 6885 |

nm |

- |

|

Peroxide index |

NF ISO 3960 |

nm |

meq(O2)/kg |

|

TOTOX (anisidine index+2x peroxide index) |

- |

nm |

- |

|

CMR, irritant and corrosive substance content |

CLP Regulation |

0 |

% |

|

Residual methanol content from transesterification |

GC-MS |

0 |

% |

|

Emissions of hazardous compounds, CMR, irritants, corrosive at 160°C |

GC-MS |

0 |

% |

|

ENVIRONMENTAL PROPERTIES |

|||

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

Biodegradability |

OECD 301 A OECD 301 C (MITI) |

> 70 > 70 |

% % |

|

Steam pressure at 20°C |

- |

0.3 |

hPa |

|

VOC content (Volatile Organic Compounds) |

- |

< 60 |

% |

|

Sulphur content |

GC MS |

0 |

% |

|

Benzene content |

ASTM D6229 |

0 |

% |

|

Total halogen content |

GC MS |

0 |

% |

|

Chlorinated solvent content |

- |

0 |

|

|

Aromatic solvent content |

- |

0 |

|

|

Environmentally-hazardous substance content |

CLP Regulation |

0 |

% |

|

Content of compounds with GWP |

- |

0 |

% |

|

Content of compounds with ODP |

- |

0 |

% |

|

Carbon assessment, life cycles analysis. |

ISO 14040 |

56.7 % |

Kg carbon equivalent |

PRESENTATIONS

|

200 L Drum

|

20 L Can

|

INSTRUCTIONS FOR USE

|

|

|

|

Degreasing with rag |

Degreasing with brush |

|

|

|

Low-pressure sprayers with water rinse from 20% in water |

Solvent parts washers from 50% in water |

|

|

|

Ultrasound tank from 20% in water |

Hot or cold immersion tanks from 50% in water |

|

|

|

Rotating or forward-travelling basket |

Spray washing machine from 20% in water |