NEUTRALÈNE® PRINT ECO 60

EMULSIONABLE DEGREASING SOLVENT

OPTIMIZED FLASHPOINT/EVAPORATION SPEED RATIO

NOT CLASSIFIED FLAMMABLE

REGULATIONS CLP CE 1272 GHS

DEGREASING IN INDUSTRIAL MAINTENANCE, IN GENERAL MECHANICS

REMOVAL OF FRESH INKS FOR FLEXOGRAPHY-HELIOGRAPHY, OFFSET LITHOGRAPHY LIQUIDS

and REMOVAL OF DE-MOULDING AGENTS

Mixture of narrow-cut hydrocarbons to obtain a high rate of evaporation for a maximum flash point. Hydrotreated by catalysis NEUTRALÈNE® PRINT ECO 60 is completely free of fragrances and benzene.

This product is intended for degreasing operations in mechanical and industrial maintenance, but its great neutrality concerning plastics allows it to be used in many other fields.

|

|

FLASH POINT 62°C NF EN ISO 2719 CLP CE 1272/2008 SGH EU Regulation 2015/1221

EVAPORATION SPEED 35mn

DEGREASING POWER 35 (Kauri Butanol index ASTM D 1133)

|

|

AREAS OF USE

Cleaning and degreasing of mechanical components, bearings, rollers, slides, racks, power transmissions, information transmissions.

Industrial maintenance.

Cleaning operation in assembly workshops.

Elimination of fresh inks in flexography and heliography printing.

Offset Lithography liquids.

Dissolution and elimination of de-moulding agents, of anti-corrosion protection waxes.

HOW TO USE IT

Use pure.

Elimination with mechanical action, rag, paintbrush, brush, low pressure sprayer.

Do not use in ultrasonic tanks.

NEUTRALENE PRINT ECO 60 can be removed with a pressurized water rinse, in a water bath or with a damp cloth.

PHYSICO-CHEMICAL CHARACTERISTICS

|

CHARACTERISTICS |

STANDARDS |

VALUES |

UNITS |

|

Appearance |

Visual |

Clear |

- |

|

Colour* |

Visual |

Colourless |

- |

|

Odour |

Olfactory |

Light |

- |

|

Density at 25°C |

NF EN ISO 12185 |

810 |

kg/m3 |

|

Refractive index |

ISO 5661 |

1.4410 |

- |

|

Freezing point |

ISO 3016 |

-50 |

°C |

|

Solubility in water |

- |

100 |

% |

|

Kinematic viscosity at 40°C |

NF EN 3104 |

1.8 |

mm²/s |

|

Acid index |

EN 14104 |

0 |

mg(KOH)/g |

|

Iodine index |

NF EN 14111 |

0 |

gI2/100g |

|

Water content |

NF ISO 6296 |

0.005 |

% |

|

Residual after evaporation |

NF T 30-084 |

0 |

% |

|

PERFORMANCE CHARACTERISTICS |

|||

|

CHARACTERISTICS |

STANDARDS |

VALUES |

UNITS |

|

Kauri Butanol Index |

ASTM D 1133 |

35 |

- |

|

Evaporation rate |

- |

35 |

min |

|

Surface tension at 20° C |

ISO 6295 |

23.6 |

Dyne/cm |

|

Breakdown voltage |

NF EN 60156156 |

63,000 |

Volts |

|

Corrosion of copper strip 100h at 40° C |

ISO 2160 |

1a |

Quote |

|

FIRE SAFETY CHARACTERISTICS |

|||

|

CHARACTERISTICS |

STANDARDS |

VALUES |

UNITS |

|

Flash point (closed vessel) |

ISO 2719 |

62 |

°C |

|

Self-ignition point |

ASTM E 659 |

> 230 |

°C |

|

Lower explosive limit |

NF EN 1839 |

0.6 |

% (volume) |

|

Upper explosive limit |

NF EN 1839 |

7.0 |

% (volume) |

|

Content of explosive, oxidizing, flammable, highly or extremely flammable substances |

CLP Regulation |

0 |

% |

|

TOXICOLOGICAL CHARACTERISTICS |

|||

|

CHARACTERISTICS |

STANDARDS |

VALUES |

UNITS |

|

Content of CMR, irritants, corrosives substances |

CLP Regulation |

0 |

% |

|

Residual methanol content from transesterification |

GC-MS |

0 |

% |

|

Emissions of hazardous compounds, CMR, irritants, corrosive at 160°C. |

GC-MS |

0 |

% |

|

ENVIRONMENTAL CHARACTERISTICS |

|||

|

CHARACTERISTICS |

STANDARDS |

VALUES |

UNITS |

|

Biodegradability |

OCDE 301 |

easily biodegradable |

- |

|

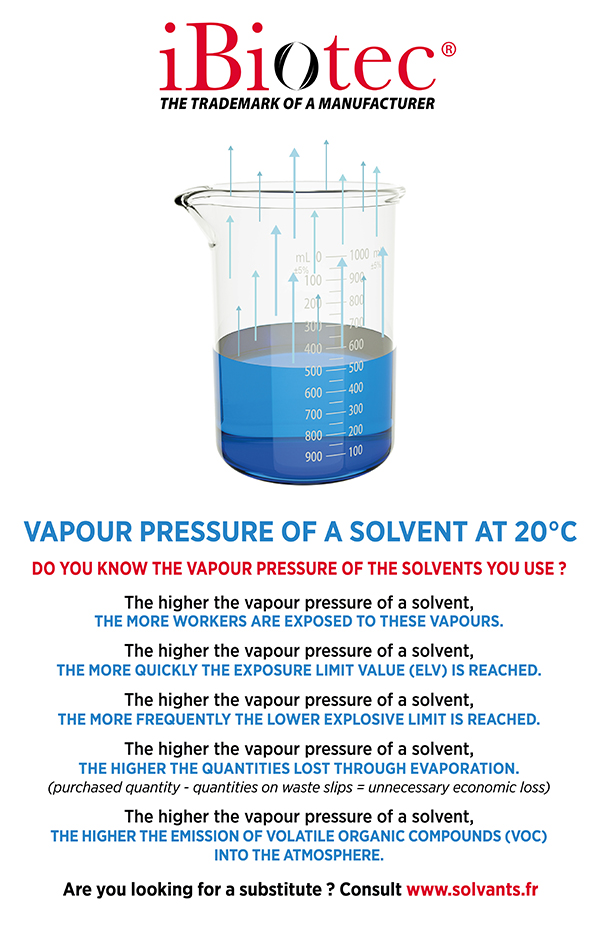

Vapour pressure at 20° C |

- |

0.38 |

hPa |

|

VOC content (Volatile Organic Compounds) |

- |

100 |

% |

|

Sulphur content |

GC MS |

0 |

% |

|

Benzene content |

ASTM D6229 |

0 |

% |

|

Total halogen content |

GC MS |

0 |

% |

|

Chlorinated solvents content |

- |

0.00 |

% |

|

Aromatic solvent content |

- |

0.00 |

% |

|

Substances dangerous for the environment content |

CLP Regulation |

0 |

% |

|

Content of compounds with PRP |

- |

0 |

% |

|

Content of compounds with ODP |

- |

0 |

% |

PRESENTATIONS

|

Container GRV 1000 L

|

Drum 200 L

|

Can 20 L |

METHODS OF USE

|

|

| Degreasing rag | Degreasing with brush |

|

|

|

Roating or translating basket |

Hot and cold immersion tanks |