DEGREASING SOLVENT FOR A3

VACUUM MACHINES

WITH RECYCLING

|

NEUTRALENE® 1089 AM MODIFIED ALCOHOLS

FLASH POINT ISO 2719 66°C DISTILLATION RANGE ISO 3405 at atmopheric pressure 182°C - 190°C

|

|

A3 solvent degreasing machines have been developed to meet the toxicity problems encountered with chlorinated solvents classified as CMR (Carcinogenic, Mutagenic, Reprotoxic).

In order to avoid any health risk for the operators, they are closed. Under vacuum, they enable the final distillation point to be lowered by about 30%, and finally they enable the recycling of solvents, for degreasing with clean products.

A3 solvents are classified into 3 families.

Hydrocarbons are all classified H 304 "May be fatal if swallowed and enters the respiratory tract". Most of the time, they have the glycol ethers (alcohols) as additives to reinforce their solvent power, which are themselves classified as H315 class 2 skin irritants, and H319 causes severe eye irritation.

Modified alcohols, which are not H 304, but remain H 315 and H 319.

Fluorinated products, the future of which is uncertain according to the F. Gas Directive. (EU Regulation 517/2014) on the environmental impact of fluorinated gases with global warming potential. This regulation is expected to be tightened further with the "Ecocide" draft legislation

In order to resolve the health risks linked to the first 2 families, users have packaging designed so that there is no possible risk of contact available to them (often through rental).

NEUTRALENE 1089 AM is part of the Modified Alcohol series, and was designed to be:

The first degreasing solvent without danger pictograms

- Elimination of security overpacks

- Reinforced solvent power, allowing use both hot and cold, extending its use in conventional solvent degreasing fountains, immersion tanks, with rotary or linear movement of baskets, ultrasonic tanks with piezoelectric or magnetostrictive generators,

- High settling power of mineral oils by density differential.

- Outdoor storage allowed, without retention, the retention obligation being subject to the Labour Code article R 4412 and the ICPE code.

Jacques P. TARDIF

Technical Director

AREAS OF USE

Cold or hot degreasing of all organic pollution, greases including solid lubricants, mineral or synthetic oils, machining fluids, shearing and stamping lubricants. RMO or MCO degreasing of all mechanical components.

TYPICAL PHYSICAL AND CHEMICAL PROPERTIES

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

Appearance |

Visual |

Clear |

- |

|

Colour |

Visual |

Colourless |

- |

|

Odour |

Olfactory |

Light characteristic |

- |

|

Density at 25°C |

NF EN ISO 12185 |

0.901 |

kg/m3 |

|

Refractive index |

ISO 5661 |

1.4160 |

- |

|

Freezing point |

ISO 3016 |

-60 |

°C |

|

Kinematic viscosity at 25°C |

NF EN 3104 |

2.3 |

mm²/s |

|

Acid value |

EN 14104 |

0.0 |

mg(KOH)/g |

|

Residue after evaporation |

NF T 30-084 |

0 |

% |

|

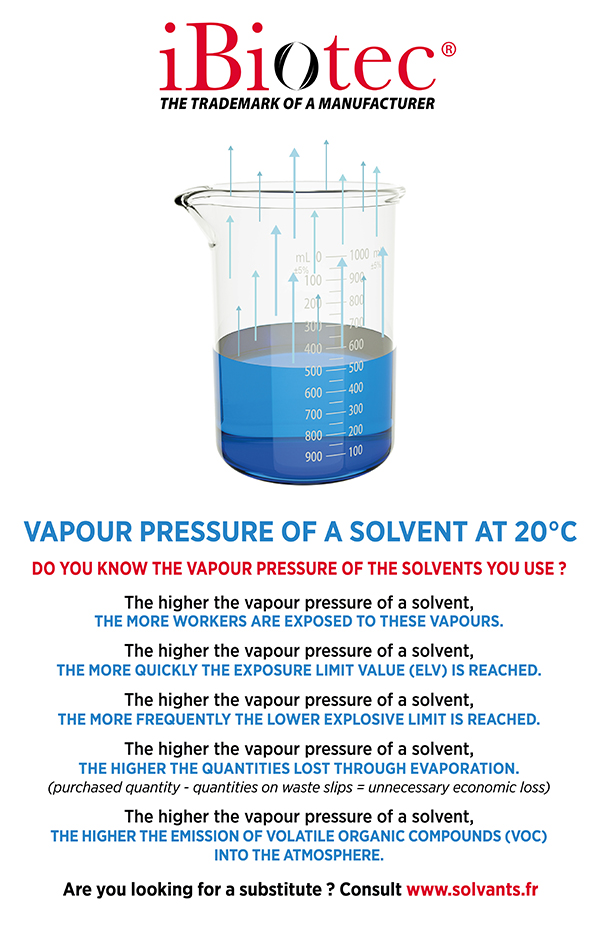

Vapour pressure at 20°C |

NF EN 13016-1 |

0.79 |

hPa |

|

Distillation range at atmospheric pressure |

ISO 3405.2019 |

182 – 190 |

°C |

|

PERFORMANCE CHARACTERISTICS |

|||

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

KB index |

ASTM D 1133 |

not applicable |

- |

|

Evaporation rate at 20°C, zero air flow |

- |

2:15 |

h.mn |

|

Surface tension at 20°C |

ISO 6295 |

26.1 |

Dynes/cm |

|

Copper blade corrosion 100h at 40°C |

ISO 2160 |

1a |

Rating |

|

FIRE SAFETY PROPERTIES |

|||

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

Flash point (vacuum) |

ISO 2719 |

66 |

°C |

|

Self-ignition point |

ASTM E 659 |

207 |

°C |

|

Lower explosive limit |

NF EN 1839 |

0.7 |

% (by volume) |

|

Upper explosive limit |

NF EN 1839 |

23.6 |

% (by volume) |

|

ENVIRONMENTAL PROPERTIES |

|||

|

PROPERTIES |

STANDARDS |

VALUES |

UNITS |

|

Sulphur content |

GC-MS |

0 |

% |

|

Benzene content |

ASTM D6229 |

0 |

% |

|

Total halogen content |

GC-MS |

0 |

% |

|

Aromatic solvent content |

- |

0 |

% |

|

Environmentally hazardous substances content |

CLP Regulation |

0 |

% |

|

Content of compounds with a GWP |

- |

0 |

% |

|

Content of compounds with an ODP |

- |

0 |

% |

USES

|

|

| solvents fountains |

rotary or linear movement of basket machines |

|

|

|

|

tanks for cold or hot immersion |

ultrasonic tanks |

|

|

|

|

spray washing machines |

A3 machines |

Download the datasheet on